Simple cover can significantly increase the efficiency of solar cells

The main reason for the growth of solar energy in recent years – an avalanche cheaper silicon cells. Yet while more than half the cost fotoelementnoy panel falls on monocrystalline silicon, expensive and energy-intensive to produce. It seems to help him hurry cheaper relatives.

Material scientists Anish Tutedzha ( Anish Tuteja ) and Bukaj Akram ( Akram Boukai ) University of Michigan (USA) tried to attract manufacturing solar cells is much lower quality metallurgical silicon, which cost ten times lower than the single crystal by incomparably less purification from impurities, which could affect the electron mobility in the material.

Such attempts have already been made, but the effectiveness of the respective solar cells did not exceed 2.6% miserable that could not possibly make a whimsical solar industry.

With the new solar battery cover on the basis of 12-micron layer of silicon metal for the first time showed the efficiency of 10.7%. (Illustration Nano Letters.)

American researchers took radically change the situation, using metal nanostructures applied to the surface of the layer of silicon metal.

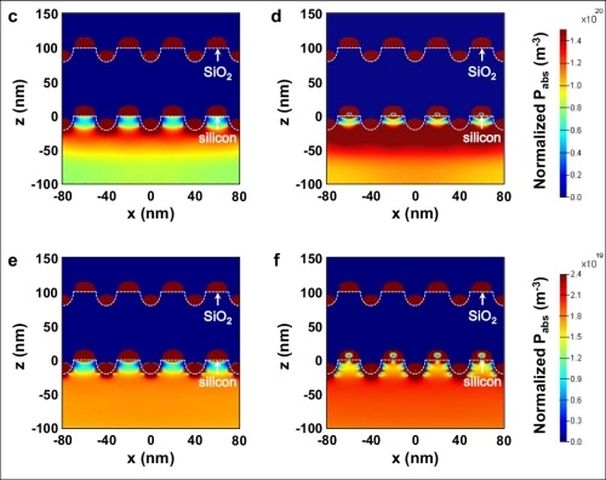

Their prototype is a cell thickness of 12 microns, on top of which are four layers of metallic nanostructures applied using block copolymer lithography. The method of manufacturing the outer layer is fully automated: as the workpiece rotation, on which is wound a thin film of polymer in the final layer using reactive ion etching creates pinholes (“pore”), a diameter of 20 nm each. At the bottom of the hole is silicon, and the edges – polymer. On top of this “sandwich” is applied superfine silver (or gold, the efficiency does not change) the film, after which the entire structure is heated and covered with glass. The described fabrication process is repeated four times, then the output obtained from such surface layer four nanostructures total thickness of 100 nm.

Thanks to the rise in metal nanostructures irradiated with visible light, surface plasmons, this relatively thin solar cell absorbs 98% of the solar radiation, converting 10.7% of the light into electricity. Yes, it is 40-45% lower than that of the best series on single-crystal silicon solar cells, but almost half the cost in mass production, as well as much less energy intensive. For comparison, recall that the solar panels amorphous silicon, monocrystalline other substitutes, in terms of efficiency does not exceed 6%.

To lumps of metallurgical silicon single crystal, it is converted to dichlorosilane / trichlorosilane, which is then purified long. New solar cells show a decent efficiency without this difficult and not cheap tehtsepochki. (Photo by Victor Borisov.)

At the same time, the authors do not find work, it all comes down to just cheapness. They intend to combine a thin layer of “second-class” conventional monocrystalline silicon photocell, using his development as a special additional coating for solar cells.

Something similar has already been undertaken in Panasonic: monocrystalline solar cells combined with a thin layer of amorphous silicon, which resulted in a record efficiency of batteries on the market. According Tutedzhi and Bukaya such combination, significantly increasing the cost of batteries, significantly raise their efficiency and commercial impact.

Report on a study published in the journal Nano Letters .